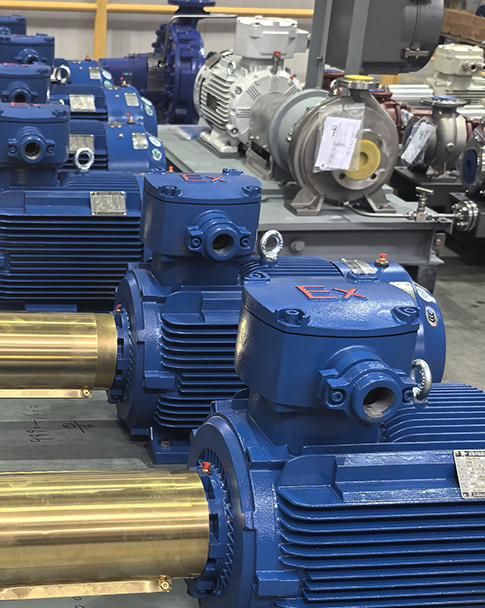

وفي المجال الصناعي، مضخات الملاط المقاومة للتآكل تعتبر المضخات الهيدروليكية والطينية من المعدات الشائعة لنقل السوائل، ولكن هناك بعض الاختلافات الهامة في وظائفها وبنيتها وتطبيقاتها.

من حيث التطبيق

تُستخدم مضخات الملاط المقاومة للتآكل بشكل رئيسي لنقل الملاط الذي يحتوي على جسيمات صلبة، والتي عادةً ما تكون صلبة ومسببة للتآكل، مثل الخام والرمل والحصى والرماد. يركز تصميمها على مقاومة تآكل الجسيمات الصلبة واصطدامها لضمان تشغيل مستقر طويل الأمد في ظل ظروف التشغيل القاسية. من ناحية أخرى، تُستخدم مضخات الطين بشكل رئيسي لنقل المواد الشبيهة بالطين، والتي عادةً ما تكون ذات جسيمات أدق وأقل تآكلًا نسبيًا، مثل طين الحفر ومخاليط الطين والماء.

هيكليا

تتميز مضخات الطين المقاومة للتآكل عادةً بمكونات تدفق أكثر متانة، مثل المكره والغلاف، مصنوعة من مواد شديدة المقاومة للتآكل لمقاومة التآكل الناتج عن الجسيمات الصلبة. كما أن أجسام المضخات أكثر مقاومة للتآكل، مما يجعلها مناسبة لبيئات الوسائط المعقدة. تتميز مضخات الطين ببنية أبسط نسبيًا، تركز على قدرات الشفط والتفريغ.

|  |

أداء

تتميز مضخات الملاط المقاومة للتآكل بكفاءتها العالية في التعامل مع الملاط عالي التركيز والكاشط، حيث توفر معدلات تدفق وضغط عالية، مع مقاومة ممتازة للتآكل. أما مضخات الطين، فتركز بشكل أكبر على التعامل مع الملاط اللزج، وتتميز بمتطلبات تدفق وضغط أقل نسبيًا.

مبادئ التشغيل

على الرغم من أوجه التشابه بينهما، إلا أنهما يختلفان في تفاصيل محددة. تستخدم مضخات الملاط المقاومة للتآكل المروحة الدوارة لتوليد قوة طرد مركزي لدفع الملاط، مع معالجة التحديات الفريدة التي تشكلها الجسيمات الصلبة. أما مضخات الطين فتركز بشكل أكبر على تحريك الملاط وتحريكه.

في التطبيقات العملية

يعتمد اختيار المضخة المناسبة على ظروف التشغيل وخصائص الوسائط. لمعالجة الملاط الذي يحتوي على كمية كبيرة من الجسيمات الصلبة وذات قابلية عالية للتآكل، تُعدّ مضخات الملاط المقاومة للتآكل خيارًا أفضل؛ أما بالنسبة للتطبيقات التي تتعامل بشكل رئيسي مع الوسائط الشبيهة بالملاط، فتُعدّ مضخات الطين أكثر ملاءمة.

باختصار، تلعب مضخات الطين المقاومة للتآكل ومضخات الطين دورًا هامًا في الإنتاج الصناعي. فهم الاختلافات بينهما يُساعدنا على اختيارها واستخدامها بشكل مناسب في مشاريع متنوعة، وتحقيق نقل أكثر كفاءة وموثوقية للسوائل.

نحن متواجدون على مدار 24 ساعة للإجابة على جميع أسئلتك.

WhatsApp

WhatsApp TikTok

TikTok