سفينة "جامبو" التابعة لشركة KSB تُبحر | بناء حاجز بيئي متين في أعالي نهر اليانغتسي

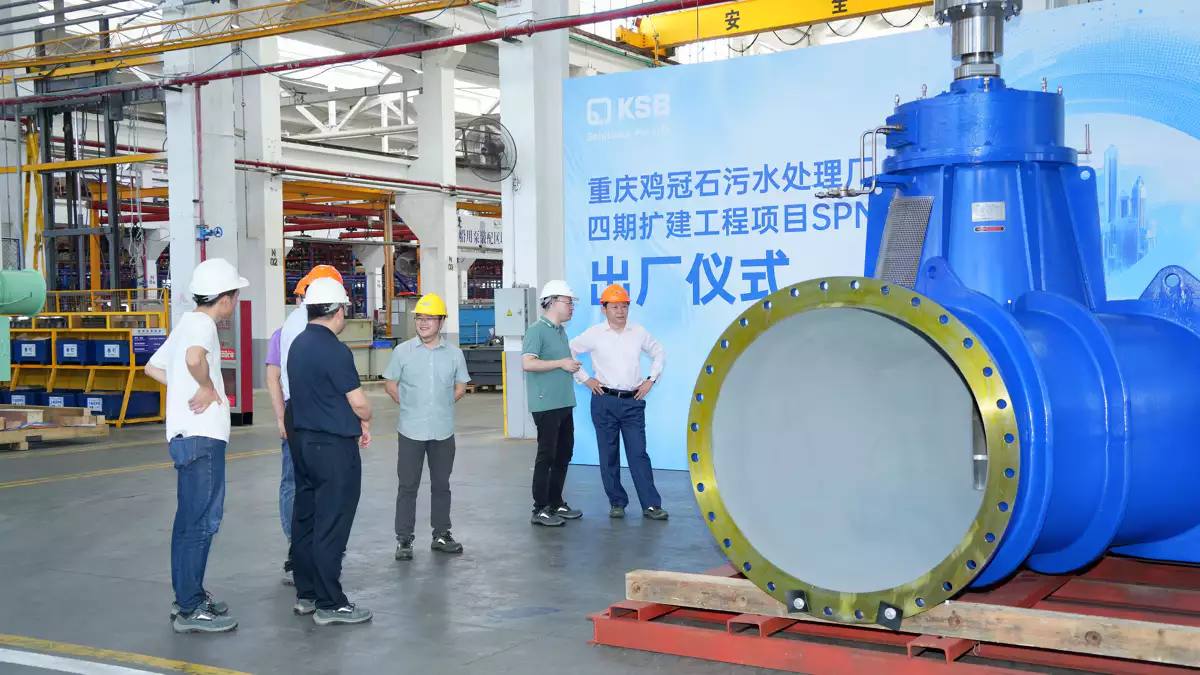

مؤخرًا، وسط ترقبٍ كبير، أُقيم حفل تسليمٍ مهيبٌ للمعدات الأساسية لمشروع توسعة المرحلة الرابعة لمحطة معالجة مياه الصرف الصحي في تشونغتشينغ جيغوانشي - مضخة مياه الصرف الصحي الحلزونية الرأسية KSB SPN 1200 - في شركة شانغهاي KSB للمضخات المحدودة. لا يُمثّل هذا التسليم الناجح لمعداتٍ حيويةٍ أخرى من KSB فحسب، بل يُشير أيضًا إلى أن مشروعًا رئيسيًا لحماية البيئة يهدف إلى حماية نهر اليانغتسي على وشك أن يُزوَّد بـ"قلبٍ محليٍّ" قوي!

يحمل مشروع التوسعة للمرحلة الرابعة لمحطة معالجة مياه الصرف الصحي في تشونغتشينغ جيغوانشي مهمة مزدوجة تتمثل في معالجة تصحيح التفتيش المركزي لحماية البيئة والمشاكل البيئية للحزام الاقتصادي لنهر اليانغتسي، مما يجعله مشروعًا رئيسيًا متوقعًا للغاية في تشونغتشينغ.

عند اكتماله، ستصل الطاقة الإجمالية لمعالجة مياه الصرف الصحي في محطة جيغوانشي إلى 1.2 مليون متر مكعب يوميًا، مما يجعلها أكبر محطة لمعالجة مياه الصرف الصحي في غرب الصين وواحدة من أكبر خمس محطات في البلاد. ستعزز هذه القدرة التنقية الهائلة بشكل كبير قدرة معالجة مياه الصرف الصحي في المنطقة الحضرية المركزية في تشونغتشينغ، مما يوفر دعمًا قويًا لبناء حاجز بيئي حيوي في المنبع العلوي لنهر اليانغتسي.

قلب "عملاق" بارتفاع 12 مترًا

إن المشاركة في مثل هذا المشروع المهم يعد شرفًا، ولكنه أيضًا مسؤولية ثقيلة: باعتبارها "قلب" نظام رفع مياه الصرف الصحي بأكمله، تواجه مجموعات المضخات التي توفرها شركة KSB تحديات غير مسبوقة.

⏺︎ حجم عملاق: تتجاوز مجموعات المضخات SPN 1200 التي تم شحنها هذه المرة 12 مترًا في الارتفاع من أسفل منحنى المدخل إلى أعلى المحرك، مما يشبه عملاقًا فولاذيًا.

⏺︎ سعة طاقة هائلة: لتحقيق قفزة نوعية في سعة المعالجة للمشروع من 800,000 طن إلى 1.2 مليون طن يوميًا، أحدثت KSB ثورة في تصميم مضخات المدخل. بتحويل ست من وحدات الضخ الرئيسية السبع الأصلية إلى مضخات SPN1200 بسعة 12,000 متر مكعب/ساعة، وإضافة ثلاث مضخات إضافية من سلسلة SPN بسعات 8,750 متر مكعب/ساعة، و5,370 متر مكعب/ساعة، و2,100 متر مكعب/ساعة، حققت وحدة الضخ المُعدّة حديثًا في KSB شنغهاي قفزة نوعية في إجمالي سعة التسليم، كما وفرت مرونة تشغيلية وموثوقية غير مسبوقتين.

⏺︎ تحدي "العملاق": فرض الحجم الهائل للوحدات وطاقتها متطلبات صارمة للغاية على الاهتزاز وأنماط التدفق وكفاءة الطاقة. كانت كل خطوة من خطوات النقل والتركيب والتشغيل اختبارًا حقيقيًا للتكنولوجيا والخبرة.

وفي مواجهة هذه التحديات، أظهر الفريق الفني لشركة KSB نقاط قوته الأساسية:

⏺︎ النمذجة الهيدروليكية المتقدمة: الاستفادة من الحمض النووي التكنولوجي لشركة KSB لضمان تصميم ممتاز منذ البداية.

⏺︎ محاكاة تدفق ديناميكا الموائع الحسابية: تحليل التوأم الرقمي لبيت المضخة بأكمله للتنبؤ بأنماط تدفق المياه وتحسينها.

⏺︎ تحليل الاهتزاز CAE: "تشخيص" كل وحدة مضخة لضمان الاستقرار القوي تحت التشغيل بسرعة عالية.

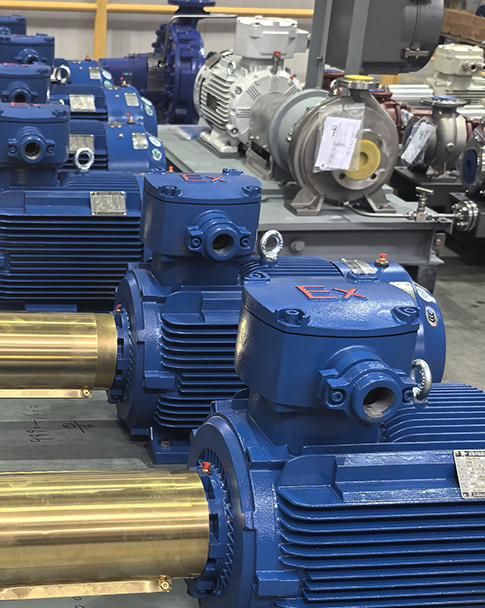

علاوة على ذلك، قدمت شركة KSB أكثر من 100 وحدة من معدات العمليات الرئيسية لهذا المشروع، بما في ذلك مضخات الصرف الصحي الغاطسة، والمراوح، والمحركات، مما يضمن التشغيل السلس للمشروع مع مجموعة منتجات شاملة.

الوفاء الدقيق بالعقد، والارتقاء إلى مستوى التوقعات

"المعايير العالية والمتطلبات الصارمة لمراقبة جودة المشروع، والتنسيق الشامل لتقدم البناء عبر مراحل متعددة" - كان هذا هو التزام المشروع واختبار لجميع الموردين.

بصفتها موردًا رئيسيًا للمعدات للمشروع، أدركت شركة KSB شنغهاي تمامًا حجم مسؤوليتها. وفي مواجهة التحديات المزدوجة المتمثلة في ضيق مواعيد تسليم المشروع والمتطلبات الفنية العالية، نجح فريق KSB في مواجهة هذا التحدي، مُظهرًا احترافية فائقة وقدرات تنفيذية قوية. وعملت جميع الأقسام معًا بسلاسة، بتنسيق دقيق في كل مرحلة من مراحل التصميم والإنتاج وحتى التسليم، مع مراقبة صارمة للجودة.

وكما كان متوقعًا، سلمت شركة KSB في النهاية الدفعة الأولى المكونة من 6 مضخات صرف صحي حلزونية رأسية وأكثر من 100 مضخة تحريك غاطسة في النصف الأول من العام، مع الالتزام الصارم بمتطلبات الجدول الزمني للمشروع.

هذا الوفاء الدقيق بالالتزامات التعاقدية ضمن سير العمل بسلاسة في المشروع بأكمله. في 30 يونيو من هذا العام، نجح المشروع في تشغيل إمدادات المياه الأولية. جميع منتجات KSB المُركّبة عملت بثبات وأداء ممتاز، مما أرسى أساسًا متينًا لنجاح المشروع على مراحل.

وراء هذا النجاح يكمن التزام شركة KSB تجاه عملائها، والتزامها بالمسؤولية الاجتماعية، وإثبات قوة "التكنولوجيا الألمانية المصنوعة في الصين".

ومع التسليم الناجح لمضخة SPN 1200، سنواصل جهودنا لاستكمال تسليم المضخات اللاحقة لهذا المشروع.

كل شحنة هي وفاءٌ بوعد، وكل مغادرة هي رحلةٌ نحو تحقيق رسالة حماية جبالنا الخضراء ومياهنا الصافية. ستواصل KSB المساهمة في حماية البيئة في الصين بتقنياتها المتطورة ومنتجاتها الموثوقة وخدماتها الاحترافية، بالتعاون مع جميع شركائها لبناء مستقبل أخضر.